We’ve been servicing the industry since 2008.

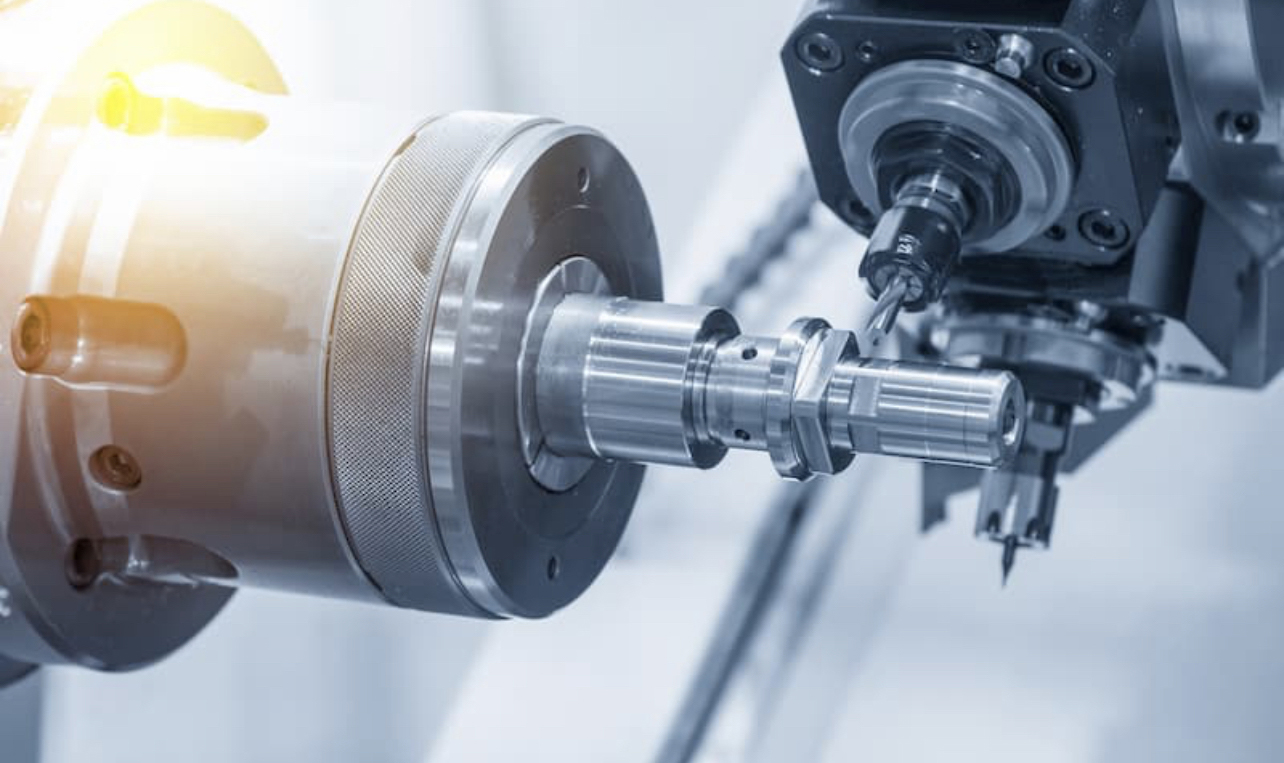

We provide high quality, accurate turned parts and assemblies to World Class OEMs industries.

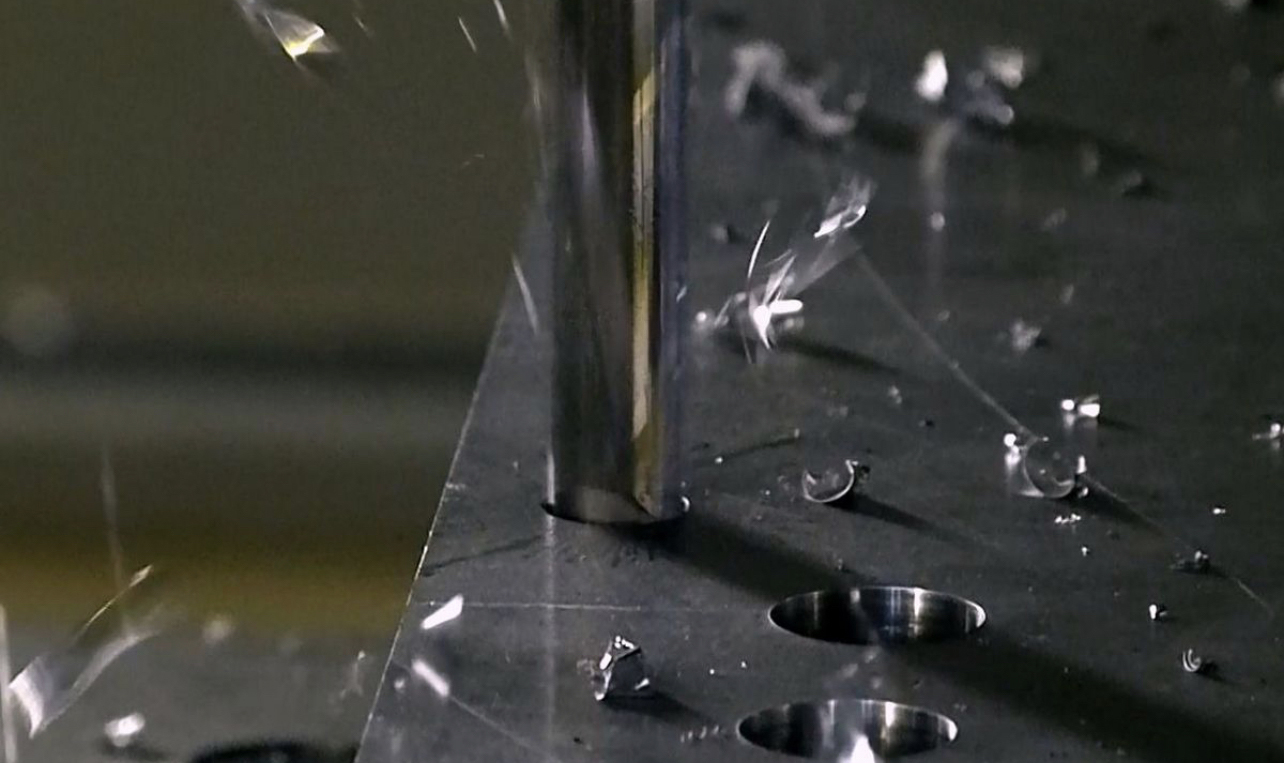

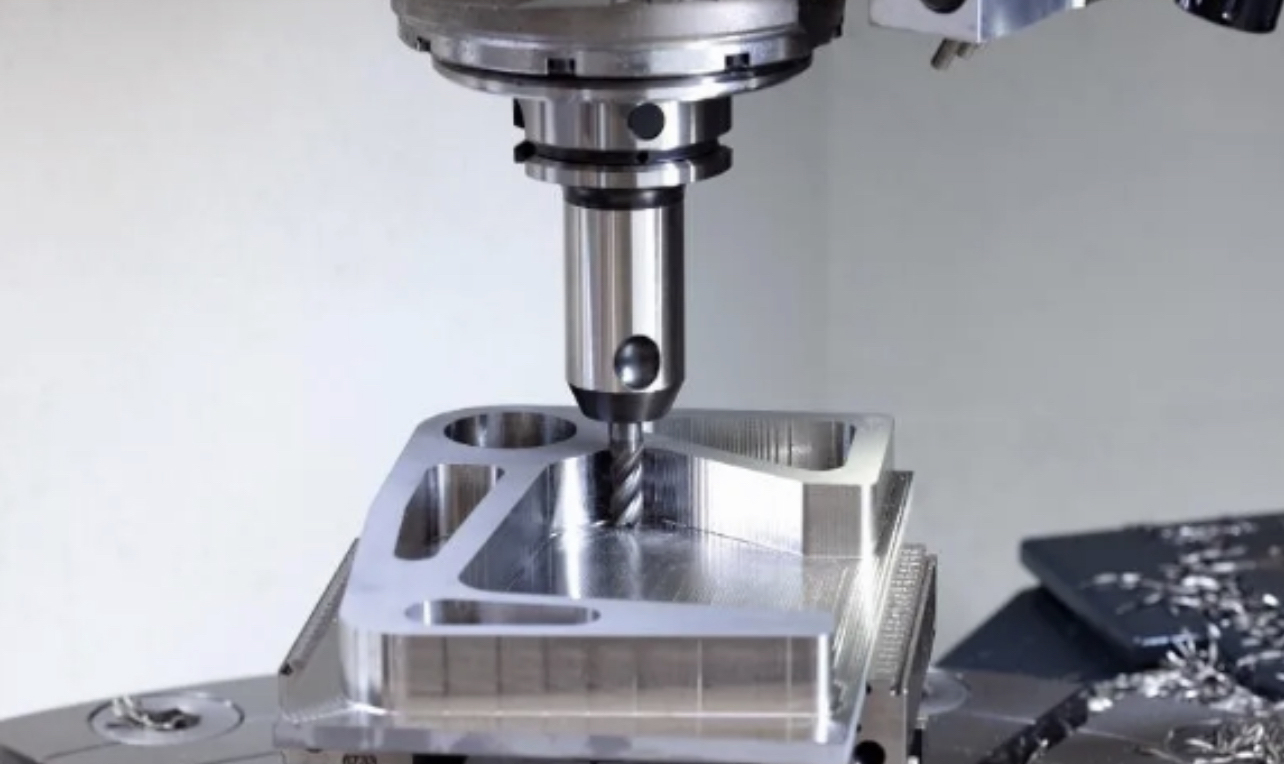

Combining advanced processing equipment and rich manufacturing experience, we are able to produce CNC turning, CNC Swiss processing and customized processing parts for various industrial applications.

Combined with advanced processing equipment and rich manufacturing experience, we are able to produce CNC turning, CNC Swiss processing and customized processing parts for various transportation applications.

We provide metal instruments and accessories for medical departments, such as mixers, heaters, medical laboratory equipment and so on. Our Swiss turning, precision machining and surface treatment capabilities

Our manufacturing is also geared to the development and operation of aircraft and aerospace. We are committed to producing precision aviation machined parts with the highest accuracy for specific applications.

The quotation will be provided within 1-2 working days after receiving drawings with specification, sizes, quantities, etc. from our clients.

The quality our customer needs is what we will provide.

Materials will be selected according to customers’ requirements and product attributes by our engineering team.

Finishes can be customized to service every special client.

The goods will be delivered to you within agreed time.

We are responsible and accountable to our customers

Ningbo Vensun Machinery Co., Ltd. was established in 2008 in Ningbo ,is a global company engaged in the engineering, design and manufacture of high precision custom solutions, mold custom solutions, casting custom solutions & wheel hub series.

VENSUN is a professional mold design&manufacturer, specializing in large and complex mold which contains plastic injection mold, die casting mold and sheet metal mold etc. Our core business strategy is to provide one-stop mold solution, which includes mold component mechanical design, mold design, mold fabrication, plastic component manufacturing and secondary processing services.

Our growth and expansion of capabilities over the past ten years have always been about providing you, our customer, with the best possible manufacturing experience in the industry. That continued evolution will never stop, and it will help shape our vision and mission as a company.

We provide high quality, accurate turned parts and assemblies to World Class OEMs industries.

VENSUN MACHINERY is equipped with professional production equipment and excellent engineering team. We will make the products they want according to the customers' ideas, and we can also make the best plan according to the customers' needs. Our core business strategy is to provide one-stop solution, which includes mold component mechanical design, mold design, mold fabrication, component manufacturing and secondary processing services.

With offices and factories in China, Vensun’s team members are dedicated to achieve customer needs through innovative solutions.